SBS Ecoclean Group Blog

A hub for insights, updates, and deep dives into the world of industrial parts cleaning and surface processing, with solutions for Precision Technologies, HealthCare, Mobility, Environment and Renewable Energy.

Your go-to resource for the latest trends, technologies and best practices with: Industry Insights, Sustainability Focus, Expert Opinions, Company Updates and Technical Guides.

The Latest Blog Posts

02/25/2026

Efficient cleaning of micro-lasered filter screens for stable extrusion processes

Micro-drilled holes, maximum requirements: How can high-precision filter screens for plastics…

more

01/27/2026

How to meet the highest cleanliness requirements in advanced manufacturing?

With its wide range of configuration and automation options, the EcoCvario easily adapts to…

more

12/12/2025

Ecoclean Contract Cleaning

Industry-specific. Flexible. Reliable.

Every manufacturer knows this moment all too well: A…

more

11/20/2025

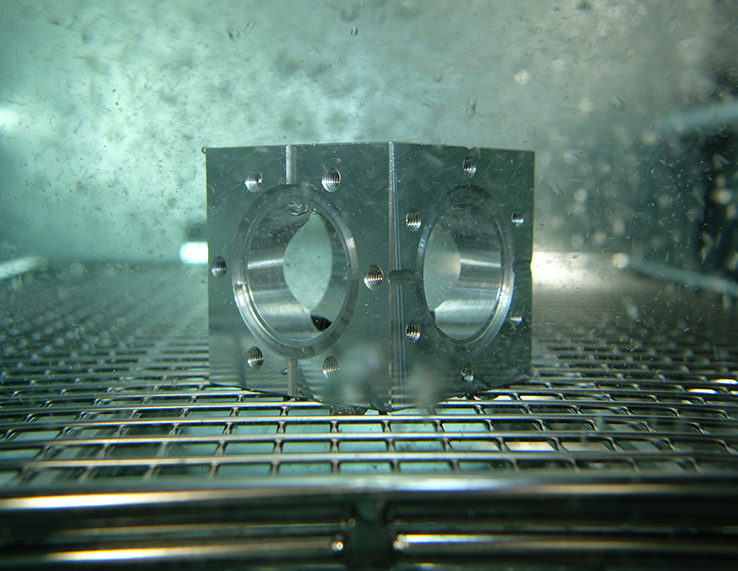

Inside Our Global Test Centers: Achieving Optimal Parts Cleaning Results

Achieving the desired cleaning results starts with the right parts cleaning trial environment. SBS…

more

09/02/2025

A Clear Focus on Cleaning Effectiveness

Our innovative APM solution has taken a major step forward: it’s now even more powerful in…

more

08/12/2025

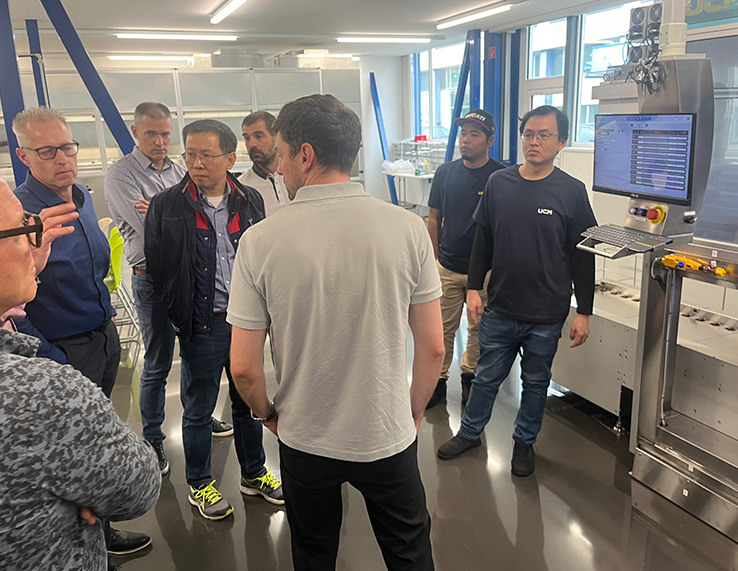

Examine and improve processes | on site with customers

In parts cleaning, we not only look at the process in which our system is used, but also at what…

more

07/22/2025

Challenge accepted: Maximum cleanliness, shortest cycle times, fragile components.

We take the example of bipolar plates and ask our expert from the Ecoclean Center of Competence in…

more

06/18/2025

Medical Device Manufacturing - Cleaning, Passivation and Final Packaging Solutions for the Medical Device Industry

Fabio Cordaro takes us on a deep dive into the most relevant topics in medical device manufacturing.

more

11/14/2024

Ecoclean responds to US customer needs and takes further steps into medical technology and systems for the local market.

In 2024, Ecoclean focused on establishing new partnerships and expanding its product portfolio to…

more

11/13/2024

Local for local: news from India and China

In 2024, the SBS Ecoclean Group strengthened its commitment to local markets in line with our core…

more

11/12/2024

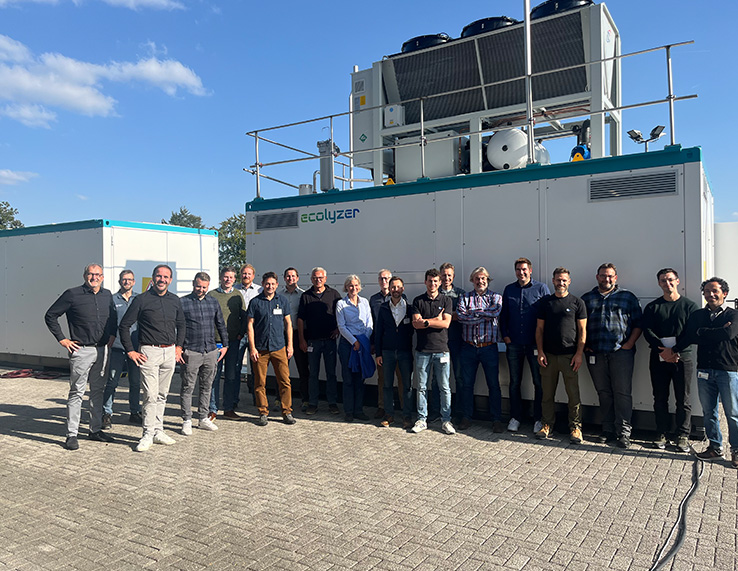

EcoLyzer: pioneering a green hydrogen future

Green hydrogen, sustainably produced by electrolysis of water, is a key enabler of the energy…

more

11/11/2024

High-Purity: Next-level industrial cleaning

The demands of industrial cleaning have never been more diverse, with new products, complex part…

more

11/10/2024

Strengthening our global presence with local expertise

With dynamic market conditions and increasing demand for innovative solutions, it has never been…

more