Increasing cleanliness requirements and complex component geometries call for innovative solutions. Our Pulsated Pressure Cleaning (PPC) process is highly effective, even in hard-to-reach areas. In this article, our parts cleaning expert, Rainer Straub, provides a detailed explanation of PPC. To illustrate, we will demonstrate how this technology can be applied using the EcoCvario as an example. The EcoCvario is a flexible precision chamber cleaning system that seamlessly integrates PPC technology in a very compact system to efficiently and sustainably meet today's high cleanliness standards.

Let's recap: What is Pulsated Pressure Cleaning (PPC)?

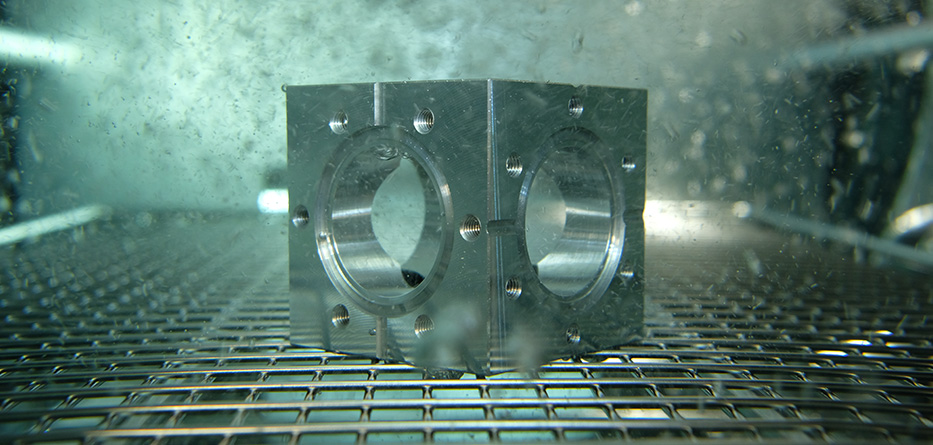

Pulsated Pressure Cleaning is a highly effective cleaning technique that uses cyclic pressure changes within the cleaning chamber. By repeatedly lowering and increasing the pressure of the cleaning medium — whether aqueous or solvent-based — vapor bubbles are formed and then collapsed. The resulting microbubbles create powerful cleaning effects through cavitation, displacement, and agitation. “These dynamic mechanisms act uniformly and effectively regardless of component geometry, making Pulsated Pressure Cleaning ideal for complex and hard-to-reach structures,” explains Rainer Straub.

Isn't it vacuum cleaning? What makes Ecoclean's version so special?

It's true that vacuum-assisted cleaning is nowadays an established principle in industrial parts cleaning. What distinguishes Ecoclean is how we've further developed this technology to meet ever-increasingly complex cleaning requirements. In short, we have elevated vacuum-assisted cleaning to a new level. Rainer Straub explains the main difference: "Our PPC technology can be used in multistage tank systems and chamber systems. It works with aqueous media or solvents. It is designed to reliably clean a wide range of component geometries and levels of material sensitivity."

To ensure optimal results for every application, the Pulsated Pressure Cleaning system from Ecoclean offers several specialized operating modes, including Basic, Soft, Booster, and Spin. Each mode is designed to address parts-specific cleaning challenges and has been rigorously tested and validated for various component geometries. This flexibility allows the customer a specific adaptation of the PPC – Cycle cleaning process, whether for sensitive surfaces, complex internal structures, or targeted rinsing tasks. The result is a highly flexible, efficient, and application-specific cleaning solution.

Images show system with optional glass fronts.

PPC in practice? This and other features of the EcoCvario.

Increasing quality standards across industries demand cleaning solutions that are not only effective, but also flexible and sustainable. The EcoCvario is designed for maximum flexibility and performance. Its modular system allows different cleaning and drying processes to be combined and tailored to the specific application. Features with many options such as Pulsated Pressure Cleaning (PPC), power-controlled ultrasonic cleaning, high-pressure cleaning for stubborn contaminants, gentle flooding, and additional nozzle bars for optimized rinsing ensure all components emerge spotless and undamaged.

Drying is equally adaptable: combinable hot air and vacuum drying, coupled with intelligent, sensor-controlled moisture control and HEPA-filtered supply air, guarantees rapid, energy-efficient drying without recontamination of your valuable components.

"The EcoCvario, equipped with PPC, offers the ultimate combination of flexibility, efficiency in precision chamber cleaning. It's the smart choice for even the most demanding cleaning tasks," concludes Rainer.

From basic options to fine cleaning features, we have everything needed for those working with the strictest cleanliness levels. Do you want your parts to be clean? Contact Ecoclean! highpurity(at)ecoclean-group.net

Visit our website to learn more about the EcoCvario: https://ecoclean-group.net/products/ecocvario/#c1099

Related blog article (Pulsated Pressure Cleaning, Smart Drying and Acoustic Performance Measurement): https://ecoclean-group.net/news/blog/detail/high-purity-next-level-industrial-cleaning/