Why Ecoclean?

Maybe your company is dealing with a seasonal production peak. Maybe a new part you are tasked with manufacturing requires a level of cleanliness you’ve never achieved before. Or maybe you can’t wait for a new investment in equipment or infrastructure to be approved. Companies looking for alternatives in industrial parts cleaning benefit from our expertise and experience when they work with Ecoclean as a contract cleaner.

When it comes to industrial parts cleaning, partnering with Ecoclean offers companies a clear advantage. As a global manufacturer of parts cleaning and surface treatment systems, we combine cutting-edge equipment with highly skilled specialists to deliver efficient, precise, and consistent results. This expertise directly benefits our contract cleaning customers.

For many manufacturers, parts cleaning is not their core business. Outsourcing to Ecoclean enables them to remain lean, focus on their strengths, and stay competitive without compromising quality.

With over 60 years of experience, Ecoclean provides customized contract cleaning services that meet the highest industry standards and individual component requirements. We support customers in the general, automotive, aerospace, medical technology, and high-purity application industries, as well as many other sectors. Our global Test Centers ensure local support and short logistics routes.

Why Contract Cleaning?

There are many reasons why companies choose contract cleaning for industrial parts:

- The need for validated processes

- Production ramp-ups

- Cash flow optimization

- Technical failures or staffing shortages

- Fluctuations in production volume

- Temporary capacity bottlenecks

- Increasing cleanliness requirements for specific workpieces

Contract cleaning is a fast, reliable, and cost-effective solution. While awaiting approval of investments in new equipment or infrastructure, companies can use the available capacity of our Test Centers to meet their needs.

Who can benefit?

Imagine having access to the same advanced technology used by global OEMs… For companies that produce in small batches or only occasionally, investing in a new parts cleaning system is often not feasible. Even large companies know that new investments take time to be approved.

Contract cleaning offers a cost-effective alternative, as customers pay for the production capacity they actually need. Companies can quickly and easily adjust production volumes as demand fluctuates. In short, contract cleaning helps manufacturers stay agile while ensuring consistent, high-quality results:

- No upfront investment

- Guaranteed results using state-of-the-art Ecoclean and UCM parts cleaning systems

- No operational effort: no operators, no overhead, no maintenance

- Optional storage and packaging at Ecoclean*

- No additional in-house laboratory requirements

High-Purity Test Center Dettingen, Germany

Parts Cleaning Trials & Contract Cleaning Services for the highest demands

Ecoclean provides at the High-Purity Test Center in Dettingen process-safe, economical, and sustainable parts cleaning solutions — for applications ranging from coarse to intermediate, precision, ultra-fine, and high-purity cleaning.

- Process development and validation

- Certified cleaning according to VDA 19/ISO 16232

- Fine, precision, and ultra-fine cleaning

- Cleanroom environments with affiliated laboratories for cleanliness testing.

Contract cleaning is especially beneficial for companies that manufacture new parts with very high cleanliness requirements. Ecoclean provides reliable solutions while companies wait for investments in necessary equipment, such as high-purity systems and clean rooms, to be approved or new infrastructure to be completed. Ecoclean also provides contract cleaning services when there is a lack of appropriately trained personnel.

High-Purity Contract Cleaning Demands?

Contact: Rainer Straub contractcleaning.filderstadt(at)ecoclean-group.net.

Do you want to see how it all works?

Watch our video to learn how Ecoclean can support your manufacturing success with our professional contract cleaning services:

Test Center Southfield, USA

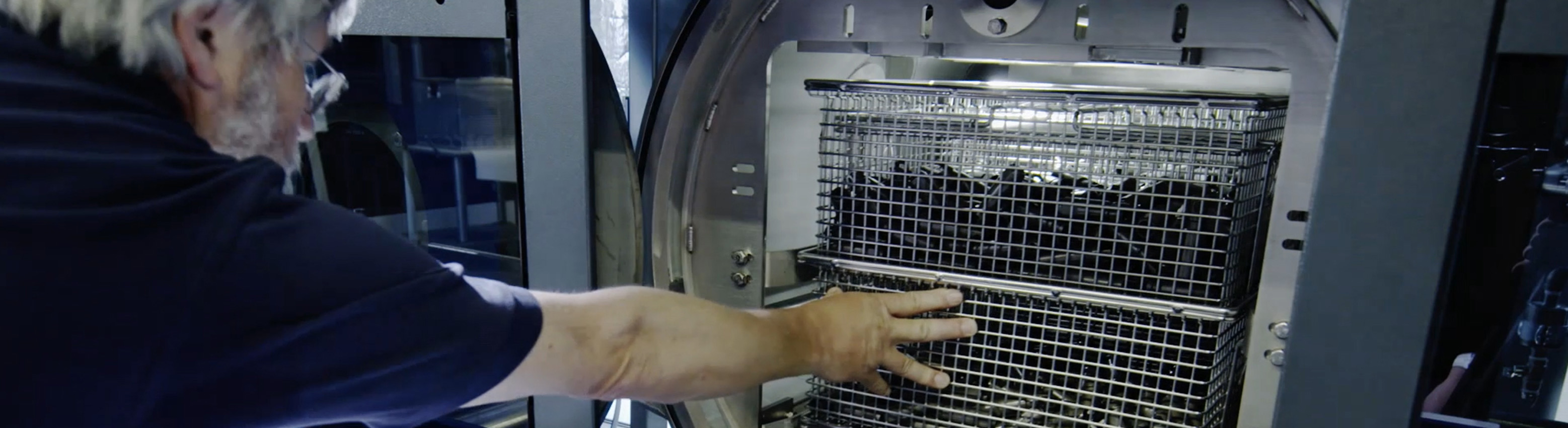

Contract cleaning is an excellent option for manufacturers who are testing new cleaning processes, working with low or variable volumes, or who need temporary support. Our Southfield, Michigan Test Center is equipped with advanced Ecoclean and UCM AG machinery, including both aqueous and solvent systems, to serve a wide range of industries.

Ecoclean, Inc. has extensive experience with cleaning trials, process development, and delivering validated results. Recently, we expanded our Test Center to expand our contract cleaning offerings as well.

Available technologies include:

- Original solvent and aqueous cleaning systems from Ecoclean

- State-of-the-art UCM original multi-tank systems for precision cleaning

- Vacuum drying chambers, and more…

Contact: Ken Chandler info.usa(at)ecoclean-group.net or fill out the contact form available in our Website to request your Contract Cleaning Services: https://ecoclean-group.us/services/contract-cleaning/

Technology Center, Biel, Switzerland

Precision Parts Cleaning AND Surface Treatment

Whether you need help with process development or want to validate parameters before purchasing a system, or if you want to outsource industrial parts cleaning and grinding using our Contract Services, our Technology Center in Biel offers a unique, all-in-one solution. We provide contract services tailored to the needs of the various industries:

- Watchmaking

- Medical Technology

- Optical

- Precision industries, and more.

Contract Services for precision parts cleaning and surface finishing

We offer validated processes for contract mass finishing and parts cleaning, as well as scalable support for prototyping, small batches, and full-scale outsourcing.

Our Technology Center is equipped with advanced technology that enables us to provide customized solutions and conduct trials under production-like conditions.

Precision Cleaning Systems (from UCM)

UCMWatchLine: Multi-stage ultrasonic cleaning system for high-precision parts cleaning, featuring configurable process steps including cleaning, rinsing, and drying.

Surface Treatment Systems (from our Swiss Partner Forplan AG)

ergospin+: Planetary finishing system designed for ultra-fine polishing and deburring, ideal for components with tight tolerances and surface finish requirements.

ergomag: Magnetic mass finishing system that enables efficient internal and external deburring of complex geometries without damaging delicate surfaces.

varyon: This new, compact mass finishing system is ideal for deburring and polishing small parts and hard materials. It generates high pressure with minimal edge rounding and risk of damage.

Contact our local experts: TechnologyCenter.switzerland(at)ecoclean-group.net

Test Center in Monschau

Where Germany is just a step away from Belgium, the Netherlands, and Luxembourg.

Operating in the heart of a border region, our Center of Competence in Monschau has built a global reputation for flexibility, innovation, and results. What our customers appreciate most is that the same Test Center infrastructure used to identify the ideal cleaning technology for new applications is also available for full contract cleaning services.

All industries — one place to be

Manufacturers from a variety of sectors rely on our Center of Competence in Monschau to solve their most challenging parts cleaning problems.

In the automotive industry, for example, customers trust our expertise in cleaning components for high-performance engines. As a center of competence for parts cleaning and surface treatment, our facility combines state-of-the-art machinery with highly trained specialists to ensure maximum precision, validated processes, and fast turnaround times.

As a center of competence for parts cleaning and surface treatment, our facility is equipped with state-of-the-art machinery, and our personnel are qualified specialists in efficient and precise manufacturing. These factors guarantee the highest quality and fastest processes.

High-Purity Cleaning for MedTech

Monschau offers medical device manufacturers contract cleaning services in an environment designed for ultra-fine cleaning. Our infrastructure includes cleanroom and allows us to:

- Develop product-specific cleaning processes

- Define and validate all relevant process parameters

- Treat every part under controlled and reproducible conditions

Contract cleaning is particularly valuable for MedTech companies facing production peaks, awaiting new investments, or in need of new infrastructure approval. Whether the demand is temporary or ongoing, the same level of care and validation we apply during cleaning trials, we offer among our contract cleaning services.

Global Test Center Capabilities

Our global presence keeps us close to our customers

Our global Test Centers determine the optimal technology* and process to achieve maximum cleanliness, featuring:

- Chamber and series immersion systems (aqueous and solvent)

- Fully enclosed, environmentally friendly solvent systems

- High-quality equipment and media

- Immersion, spray, high-pressure, and injection-flood cleaning

- Vacuum-based Pulsated Pressure Cleaning (PPC) for complex geometries

- Ultrasound / Ultrasound Plus

- Preservation / passivation

- Multiple drying methods

*Technologies vary by location. Contact your nearest Ecoclean site to confirm availability: https://ecoclean-group.net/contact/