Why is this a special topic for industrial parts cleaning?

Bipolar plates consist of 2 layers (cathode and anode), usually made of uncoated stainless-steel alloys or coated stainless steel carriers, which are extremely thin and very sensitive. The raw material for manufacturing metal bipolar plates is usually unwound from a coil. This means that impurities of an unknown nature may already be present on the raw material. The material for the plates is formed, cut, and stamped using special oils.

In addition to filmic contamination, these processes also generate particulate contamination such as flake burrs, cutting chips, fibers and general contaminants from the air.

The requirements for cleanliness are very high, as any particle that is not removed can later cause a problem in the functional process. In addition, such plates are manufactured at very high production speeds - the cycle time per part plays a very important role. Part cleaning solutions must be optimally integrated into this process.

How important it is to know the exact origin of the contaminants we want to remove?

To answer this question, we need to look at one of the most important steps in the production of bipolar plates: In a process known as "joining," the anode and cathode plates are placed on top of each other and typically welded together by laser. The welding process can be a source of contamination, which can adversely affect the subsequent performance of the fuel cell.

As can be seen in the picture above, one of the possible contaminants that can appear on such a bipolar plate are sootmarks.

These are usually caused by residual organic matter or oil particles on the surface that burn off during the welding process.

We at Ecoclean go back a few steps in the production cycle and take a close look at all the process steps.

We do this because it is important to know in advance what kind of contaminants are involved.

With our experience, we can advise our customers at this stage to use oils that can be removed later without leaving any residue.

Our solutions are therefore not just about parts cleaning, but also about improving production processes.

What else can we get clean with the industrial parts cleaning technology developed for bipolar plates?

With our technology, we can clean not only flat bipolar plates, but also cubic components such as electronic components or housings, i.e. various metallic materials with high cleanliness requirements and short cycle times.

This also includes components such as battery cell cups, heat sinks or battery connectors.

The cleaning of small parts, pre-punched as an endless belt, can also be cleaned in one piece.

Every particle that is not removed can cause problems later. Therefore, cleaning requirements are very high and require experience and expertise.

Let's take a look at how Ecoclean can support the manufacturing process, using the production of bipolar plates as an example:

For example, bipolar plates for automotive fuel cells are made from pressed graphite powder or stainless steel alloys.

The surfaces of these workpieces are usually contaminated with various substances and elements generated during the manufacturing process.

We have a lot of experience in this area - the following production steps involve forming and cutting the coil material. Oils and emulsions used in these processes can also contaminate the plates.

As mentioned earlier, oxides and sootmarks can also occur later when the plates are joined.

It is extremely important to clean the plates before subsequent processes such as coating, etc. We are able to guarantee the required particulate purity, degreasing and removal of contaminants.

This is the only way to ensure that a dense and perfectly coated bipolar plate is later used in the fuel cell and that the maximum power yield is achieved. We are active in final cleaning, surface preparation and treatment. Here we offer very efficient solutions.

What cleaning processes are applied?

There are several cleaning processes on the market. Each manufacturer must carefully weigh the pros and cons before making a decision.

For example, one solution on the market is CO2 blasting. However, we view this very critically because the bipolar plates are typically used in PEM (proton-exchange membrane) fuel cells to minimize CO2 emissions.

The use of CO2 blasting as a cleaning process is possible, but in our opinion contradictory when you are producing something that should be a more environmentally friendly solution.

Also, the high consumption of CO2 gas and compressed air is a cost factor that needs to be evaluated before a decision is taken. We see this process as more of a partial solution, good for selectively removing traces of smoke on a manageable scale. We do not recommend relying on it for the entire cleaning process.

Other solutions that manufacturers can use either individually or in combination.

We have obtained very good results in cleaning bipolar plates with steam, i.e. hot air processes. It is a fast process that is very effective, especially in removing stains and substances, while using very little liquid. When used correctly, this process allows the oil to evaporate without leaving any residue. The right temperature curves are crucial here.

Depending on the surface, we have also achieved good results with our hydro-cleaning process. We use nozzles that release the medium at a certain pressure and temperature.

To complement the cleaning process, we use other technologies such as ultrasonic cleaning, pressure-cycling rinsing or plasma cleaning, depending on the level of contamination and requirements.

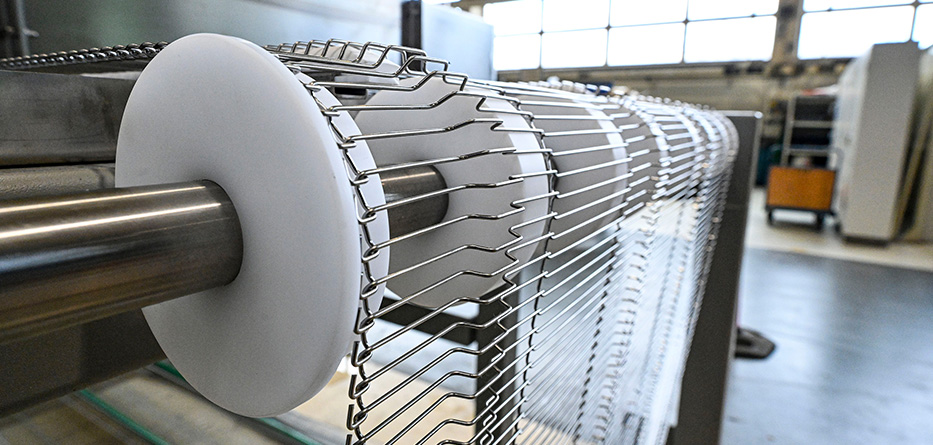

In addition to water- or solvent-based chamber systems such as the EcoCwave or EcoCcore or one of the ultrasonic in-line immersion systems from UCM AG, we now offer the GEN-2 series EcoCbelt as a system for cleaning bipolar plates.

This is a continuous cleaning system in which all possible process variants such as spray cleaning, steam cleaning, plasma cleaning, hydro cleaning, CO2 blasting and drying can be implemented as required in the system concept.

The transport system is designed for sensitive components such as electronic components, bipolar plates, etc.

Is it possible to test component, contamination, and the production requirements in advance?

At our Center of Competence in Monschau, Germany, we are able to perform tests on originally contaminated components under very close to production conditions. Our laboratories are equipped with test methods such as surface tension, fluorescence analysis and infrared spectroscopy. Not only the cleaning processes but also the cycle times are tested in our facilities.